Brush Filling Material

We have 25 years experience in the brush making industry . To insure the brush quality we are working with the good quality filament company that we have cooperated for long time. At the same time , we also keep large range of different brush filament in stock so that can produce the brushes in short time to finish customers quick order .

General Filament Characteristics

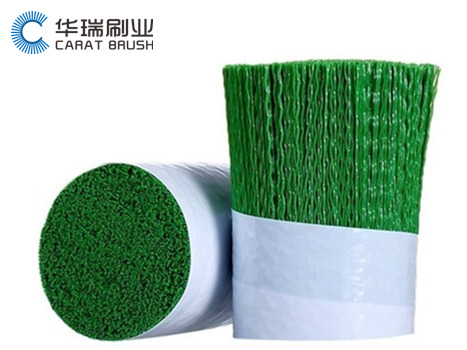

There are two kinds of synthetic filament --crimped and straight filaments .The crimped filament with the waves and the straight filament is level .

To produce the same size brush, if fill in with the crimped filament it will be looked more density .But due to it is crimped there are some gap between the filament so there are some residue will be left . And the level filaments tend to group together more and are better suited for brush seal applications.

When choosing filament ,different length and diameter will have different hardness .

-

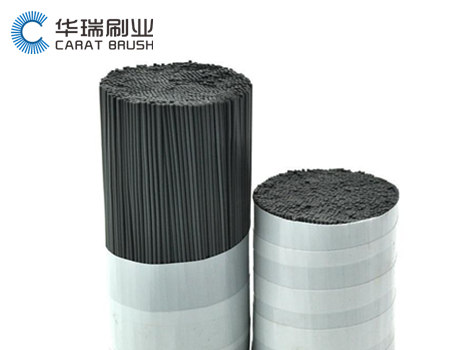

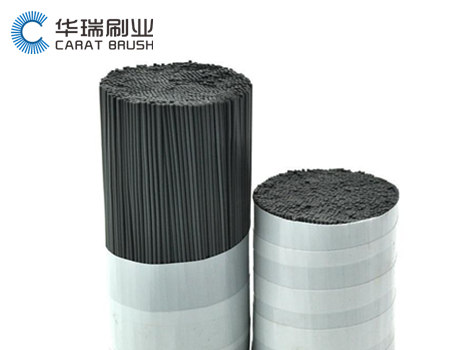

Crimped Filament

-

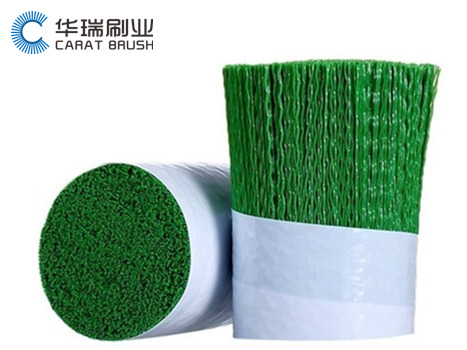

Level Filament

Filament Colors

The color of the filament can be customized ,mostly black , white ,nature color is common .The nature color contain with nothing color additive .it is looks like white color but lighter than the white color .some another nature color also shows gray color . So if you need the real white color then we will suggest to use the white color instead of nature color .

-

Black Color Filament

-

Natural Color Filament

Brush Filling Material

There are various brush filling material ,such as synthetic filament , animal hair ,nature plant fiber,wire,etc . different filling material use in different field. Different filling material for different application as below .

Nylon

Polyamide is commonly known as Niron (Nylon), the English name Polyamide (referred to as PA), the density of 1.15g/cm3, is a molecular backbone containing a repeated amide group [NHCO] - the general term of thermoplastic resin.

Nylon is commonly divided into three grades: Nylon 6, nylon 66, and nylon 612.

They have the following characteristics:

①high flexibility, excellent elastic memory, bending the restoring force, first-class work ability; ②the excellent resistance to chemical reaction, anti fouling, excellent wear resistance; ③it can work under high temperature, withstand high temperature sterilization;④the low water absorption rate; ⑤the surface spalling will not appear.

Nylon 612 is a relatively high quality nylon silk, its water absorbability low, restorability and wear resistance are better than nylon 66. In addition, nylon 612 has the characteristics of anti mildew and antibacterial, and its brush wheel and brush bar are often used in food, medical and electronic related industries.

Antistatic nylon,Flame retardant nylon.

-

Nylon 6

-

Nylon 66

Abrasive Filament

Abrasive filament is made of nylon 6 or nylon 612 as a raw material to add silicon carbide (SIC) or alumina (AO) abrasive particles after the synthetic wire, the industry also into the abrasive wire or grinding wire, the finished brush product has a resistance Grinding characteristics, according to the diameter and mesh a variety of different, commonly used in the PCB surface treatment, galvanized sheet pickling line, and metal processing, polishing deburring and so on.

-

Abrasive Filament

-

Abrasive Polishing Brush

Polypropylene (PP)

Polypropylene (referred to as PP), is a thermoplastic resin obtained by the polymerization of propylene. PP is characterized by the largest density of less than 1, the test material can be desirable when the wool material placed in the water, if floated on the surface can be initially judged as PP material; PP hair was oval cross-section; In addition, PP less flexible, It is difficult to restore the original after repeated bends; heat-resistant to 120 degrees Celsius, suitable for industrial dust removal and cleaning for the more rugged components, such as mining dock dust, sanitation trucks sweeping brush, etc.;

-

Level PP

-

Crimped PP

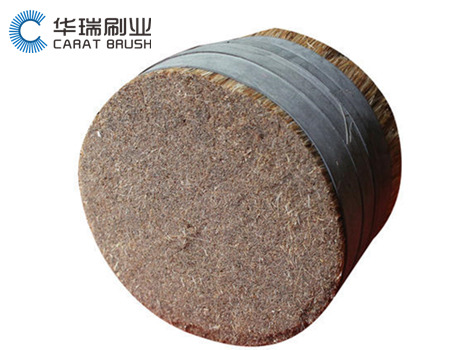

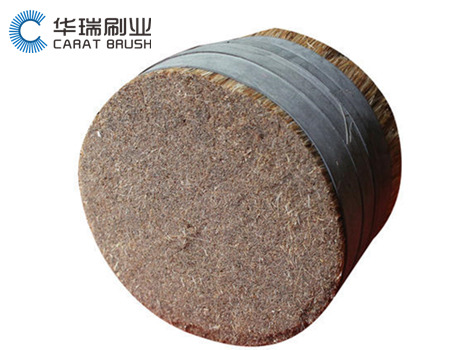

Natural Plant Filament

White brown is made of agave stems and leaves of some fibers processed from wool, mainly produced in Mexico, so the line is called "Mexican white brown"; white brown acid and alkali good performance; because of its own plant fiber so water absorption Good; white brown can be 140 degrees Celsius temperature, suitable for the manufacture of leather polishing brushes detail polishing job. In addition, there are sisal, is also used to process the brush one of the natural materials, sisal performance and white brown similar, but also used to process more into a polishing brush, finished product commonly known as "sisal."Sisal brush silk, with good toughness, high temperature, grease, commonly used in pots or high temperature brush, to the use of oil and other purposes.

-

Tampico

-

Tampico Strip Brush

Horsehair

Horse hair softness between the bristles and wool between the horse tail hair harder than pig bristles; horse hair toughness, wear resistance, but not Naisuan Jian, brushes and more used in polishing, cleaning, dust removal And other related industries; horse hair wool brush material resistant to about 190 degrees Celsius. Horse hair bristle than soft, easier to remove floating dust, often used in high-end household cleaning products, or for industrial use such as the removal of ash;

-

Horsehair Filament

-

Horsehair Cup Brush

Hog Bristle

Common bristle colors are brown (white) or black. Bristle excellent durability and water resistance, but also anti-static, high temperature and acid-base. Bristles commonly used in bath brush or precious objects polishing, such as gold, precious stones, piano and other surface treatment, but also for carbide polishing;

-

Hog Bristle Filament

-

Hog Bristle Brush

Goat Hair

Goat hair is relatively soft, slightly less elastic, made of wool brush, used to brush the paint brush will not leave marks, with excellent polishing and cleaning performance, it is non-conductive.

-

Solid Color Goat Hair

-

Variegated Goat Hair

Metal Filament

Metal wire alias (ripple brush wire, cut off the brush wire, straightening brush wire, etc.). Among the more common materials are: stainless steel wire, copper wire, steel wire, galvanized steel wire, copper wire, copper clad aluminum wire. Metal brush wire processing methods are divided into two types: corrugated wire (corrugated metal wire and then cut off); cut off the wire (the wire straightened and then cut off). Metal wire is generally used for deburring metal surface treatment, the wear resistance is good.

-

Stainless Steel Filament

-

Brass Filament